Designing for Magnetic Neutrality: How Non-Magnetic RF Components Improve Signal Integrity

In high-performance RF systems, magnetic interference can be a silent disruptor—introducing noise, distorting signals and compromising system accuracy. For engineers working in sensitive environments such as quantum computing, medical imaging, aerospace and defense, the use of non-magnetic RF components is increasingly critical.

Non-magnetic RF components—including RF cable assemblies, RF connectors and RF coaxial cable—are specifically engineered without ferromagnetic materials like nickel or steel that can create unwanted magnetic fields. Instead, they use materials such as brass, aluminum and beryllium copper to maintain magnetic neutrality while preserving electrical performance. These components are designed to carry RF signals with minimal loss and without altering nearby magnetic environments, making them ideal for sensitive systems like MRI scanners, quantum computers and precision test setups.

This article explores the engineering principles behind non-magnetic RF components and how they contribute to cleaner signal paths and more reliable system performance.

The Problem with Magnetic Materials in RF Systems

Ferromagnetic materials such as nickel, iron and certain types of stainless steel can generate unwanted magnetic fields within RF environments. These stray fields have the potential to alter impedance and phase characteristics, introduce frequency drift and phase noise, and disrupt magnetic-sensitive equipment like MRI coils and magnetometers. They can also make calibration and testing procedures more complex. In systems that operate at high frequencies or demand exceptionally low noise floors, even minimal magnetic contamination can significantly degrade overall performance.

Material Choices for Non-Magnetic RF Connectors and Cables

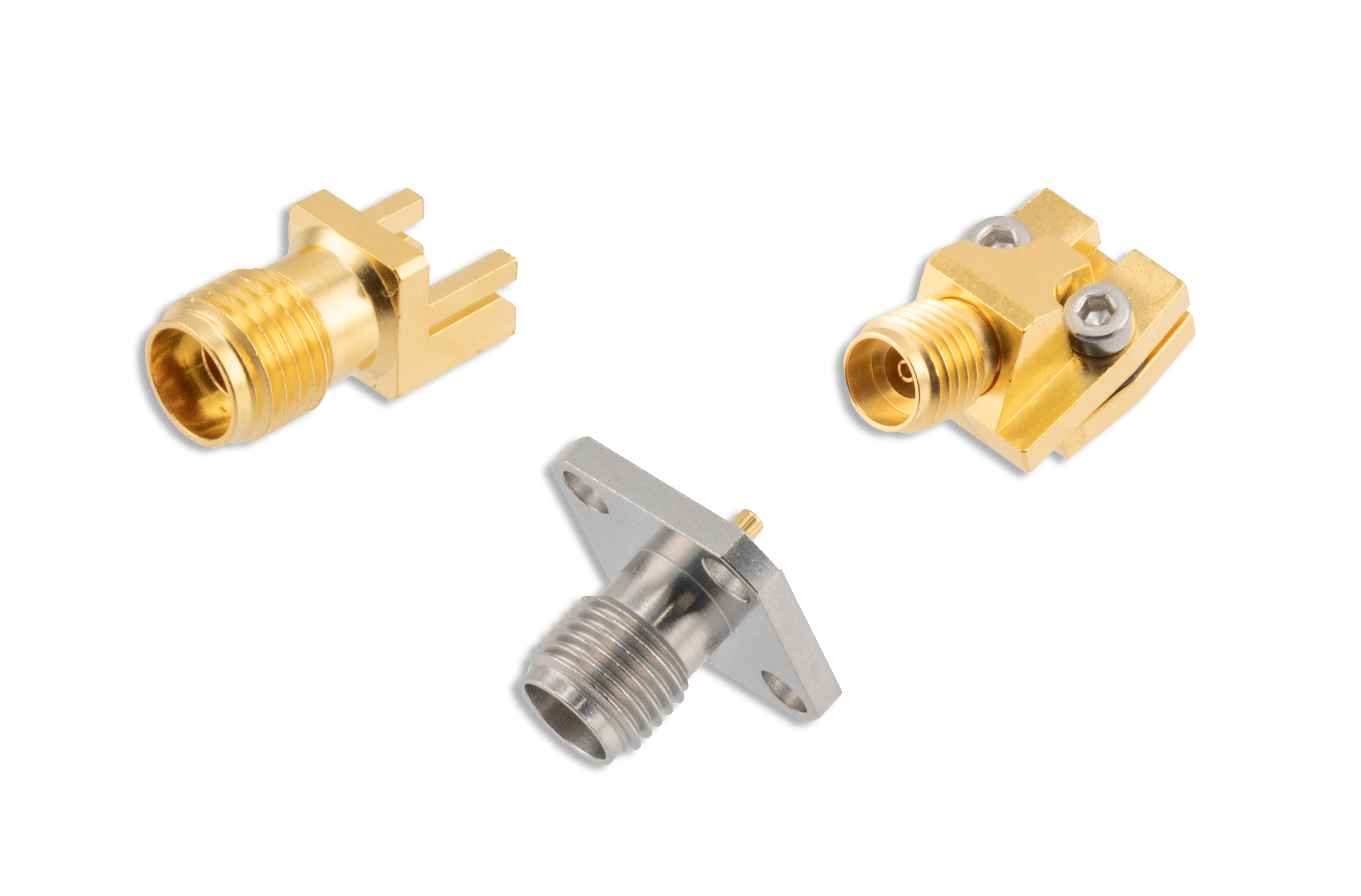

To eliminate magnetic interference, non-magnetic RF components are constructed using:

- Brass or aluminum for connector bodies

- Beryllium copper (BeCu) for spring contacts

- Silver or gold plating (avoiding nickel)

- PTFE dielectric for thermal and electrical stability

These materials ensure magnetic neutrality while maintaining mechanical durability and consistent RF performance. When evaluating non-magnetic components, engineers should also consider manufacturing tolerances, plating consistency and connector geometry, as these factors can influence impedance control and overall signal reliability.

Key Performance Features to Look For

When selecting non-magnetic RF cable assemblies, connectors and coaxial cable, engineers should look for several key performance features that ensure reliable, low-interference operation:

- Zero Magnetic Interference: Components should use non-magnetic materials throughout to prevent signal distortion in environments like MRI systems, particle accelerators and precision test setups.

- High-Frequency Performance: The best non-magnetic designs support frequencies up to 40 GHz, making them suitable for demanding aerospace, defense and advanced communications applications.

- Superior Shielding: Look for shielding effectiveness above 165 dB to minimize EMI and protect signal integrity in high-performance systems.

- Semi-Rigid Flexibility: Semi-rigid coax types such as Fairview’s FM-SR047CU-NM enable formable routing with stable electrical characteristics, ideal for tight spaces and custom installations.

Application Examples

Application

|

Benefits of Non-Magnetic RF Components

|

Defense and Aerospace

| Non-magnetic coax reduces interference with onboard magnetometers and altitude control systems, ensuring accuracy in navigation, sensors and communications in aircraft, satellites and submarines. |

Quantum Computing and Cryogenic Systems

| Experiments involving superconducting qubits or beam steering require magnetically clean environments—making non-magnetic RF cables essential. |

Medical Imaging (MRI, MEG)

| Non-magnetic RF connectors and cables prevent distortion of magnetic fields used in imaging, preserving resolution and diagnostic accuracy. |

High-Frequency Communications

| Non-magnetic, semi-rigid cables (e.g., 0.047-inch and 0.086-inch diameter) support frequencies up to 109 GHz, making them suitable for mmWave and 5G testing setups. |

Precision Test and Measurement

| In labs or production environments where magnetic interference could skew results, non-magnetic RF terminations, connectors and cables ensure accurate data. |

Summary

As RF systems evolve toward higher frequencies and more sensitive applications, the need for non-magnetic RF connectors, non-magnetic coax and non-magnetic RF cables becomes increasingly important. By eliminating magnetic interference and enhancing RF shielding, these components help engineers achieve cleaner signal paths, better system accuracy and more reliable performance.

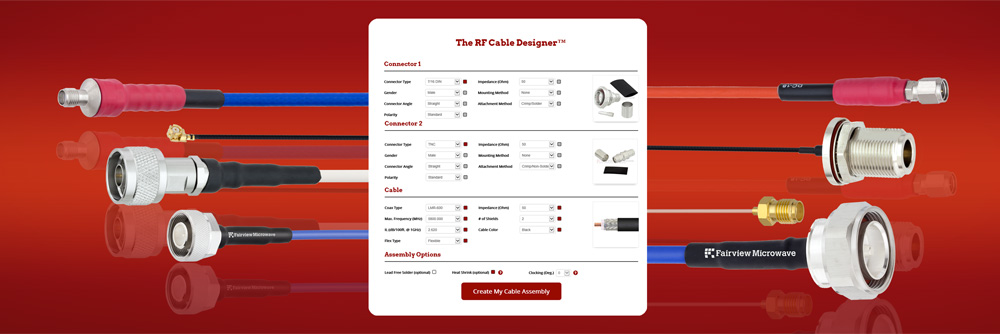

Fairview Microwave’s comprehensive line of non-magnetic RF cable assemblies, connectors and PCB components provides reliable, precision-engineered solutions for magnetic-sensitive applications across industries. Explore our non-magnetic offerings here.