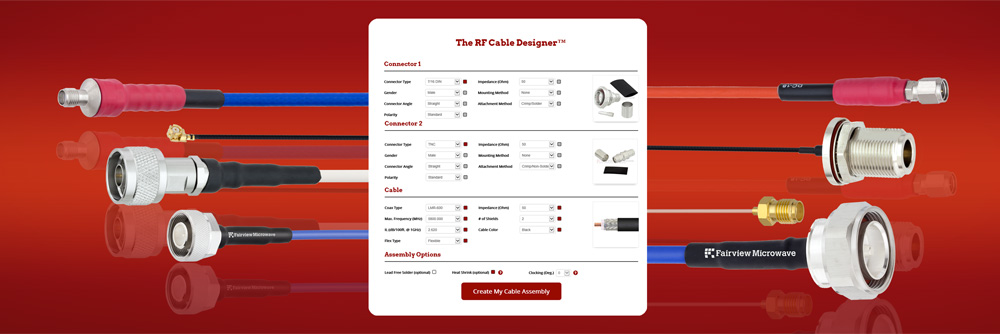

Announcing: The Coax Cable Webinar That Will Save Your Signal & SDR Setup

by Peter McNeil | Mar 18, 2025

Every RF engineer, SDR enthusiast, and telecom technician knows that cable selection can make or break signal performance. But what if you’re making a critical mistake without even realizing it?

Here’s the truth: Using the wrong coaxial cable can destroy your signal integrity, introduce interference, and render your SDR setup useless. Worse still, even if you pick the right cable, a bad termination method can create hidden weaknesses—leading to signal loss, inefficiencies, and expensive troubleshooting.

If you’re not 100% confident that you’re selecting and terminating coaxial cables correctly, then you’re playing a dangerous game with your RF performance.

But there’s good news: You can fix this.

Join the Experts & Learn How to Select and Terminate Coax Cables the Right Way

On March 26, 2025, at 2:00 PM (London time), two industry veterans—Amar Ganwani and Spencer Rautus —will reveal the step-by-step process to choosing the perfect coaxial cable and ensuring flawless termination for SDR and RF applications.

In this LIVE webinar, you will learn:

✅ The #1 mistake that ruins signal transmission—and how to avoid it.

✅ How to decode cable specifications to select the perfect cable for your needs.

✅ The hidden pitfalls of termination methods and how to prevent them.

✅ A live demonstration of best practices for soldering, crimping, and splicing.

✅ How to match your coaxial cable to any environment or application

✅ The real reason why most SDR setups underperform—and how to fix it.

Meet Your Industry Experts

🔹 Amar Ganwani – Senior Product Line Manager at Fairview Microwave (20+ years in RF & Microwave tech).

🔹 Spencer Rautus – RF Cable Assembly Product Associate at Fairview Microwave (7+ years of expertise).

🔹 Jordan Ratcliffe – Your host from the element14 Community, leading the Q&A session.

This Knowledge Could Save Your Next Project—Secure Your Spot Now

❌ Miss this webinar, and you risk wasting hours troubleshooting preventable signal issues.

✔️ Attend, and you’ll walk away with practical, expert-backed solutions to get your coaxial cable setup right the first time.

📅 Date & Time: March 26, 2025 | 2:00 PM – 3:00 PM (London)

📍 Location: Online

Related articles

Spencer Rautus | Dec 01, 2025 | RF Cable Assemblies

In RF and microwave engineering, the term “non-magnetic” refers to materials and components that exhibit extremely low magnetic susceptibility—meaning they neither generate magnetic fields nor interact with external ones in any significant way. This property ensures minimal field distortion, which is critical in applications that rely on magnetic precision or ultra-sensitive signal environments.

Typical RF components, such as cables, connectors, and adapters, are often constructed from materials like nickel, steel, or brass all of which can have measurable magnetic properties. In contrast, non-magnetic components are carefully engineered using materials such as brass with gold plating, beryllium copper, or stainless-steel grades 303/304 (non-magnetic versions).

The goal of non-magnetic component design is to make these parts “magnetically invisible,” ensuring that they do not distort the surrounding field or interfere with nearby sensors or measurement instruments. This concept is especially crucial in environments where magnetic fields play an active role such as MRI systems, particle accelerators, or quantum computers.

Why Non-Magnetic Components Matter

Even trace magnetic interference can have significant consequences in high-frequency or magnetically sensitive systems. Non-magnetic RF and microwave components are not just about material selection—they represent an engineering commitment to signal fidelity, measurement accuracy, and operational stability in critical applications.

1. Magnetic Field Compatibility

In magnetic environments such as inside MRI scanners or near high-field magnets—ordinary RF components can distort the magnetic field lines. This distortion leads to inconsistent system performance, measurement inaccuracies, and in medical contexts, artifacts in imaging results. Non-magnetic components prevent these disturbances by maintaining field uniformity.

2. Precision in High-Sensitivity Measurements

Laboratories and metrology systems that perform ultra-precise measurements—like low-noise amplification, time-domain reflectometry, or cryogenic signal testing—require zero magnetic bias. A component with residual magnetism can introduce a measurement offset, leading to unreliable data and potential calibration errors.

3. Electromagnetic Compatibility and Signal Integrity

Magnetic materials can induce eddy currents or cause phase and amplitude shifts when exposed to alternating fields. In high-frequency RF systems, this results in degraded VSWR (Voltage Standing Wave Ratio) performance and higher insertion loss. Non-magnetic components maintain clean signal transmission, ensuring predictable system behaviour.

4. Safety and Reliability

In environments where strong magnetic fields coexist with sensitive electronics, magnetic materials can become physically attracted or displaced, posing mechanical risks. Non-magnetic designs eliminate this risk, ensuring both safety and mechanical integrity.

Key Applications and Markets for Non-Magnetic RF Components

1. Medical Imaging and MRI Systems

One of the most critical areas where non-magnetic RF components are indispensable is Magnetic Resonance Imaging (MRI). MRI scanners rely on extremely stable and uniform magnetic fields often ranging from 1.5 to 7 Tesla to produce high-resolution anatomical images.

If any magnetic component is introduced into the MRI environment, it can distort the main magnetic field (B₀), resulting in signal artifacts, geometric distortions, and compromised image quality. Furthermore, magnetic materials can become dangerous projectiles in the scanner bore due to the intense magnetic pull.

To prevent these risks, non-magnetic RF connectors, cables, and adapters are used throughout MRI systems—from coil connections to external test interfaces. They maintain electrical performance while being completely inert to the magnetic field, ensuring accurate imaging and patient safety.

2. Defense, Aerospace, and Space Systems

In aerospace and defense environments, systems such as radars, navigation modules, satellite communications, and avionics depend on precise RF performance under extreme conditions. The presence of ferromagnetic materials in these systems can compromise sensor calibration, signal directionality, and radar cross-section management.

Non-magnetic RF components are favored because they:

- Maintain consistent electrical performance in magnetically variable environments.

- Reduce electromagnetic signature, improving stealth characteristics.

- Withstand radiation and vacuum conditions, essential for space applications.

For satellites and spacecraft, magnetic materials can interfere with onboard magnetometers or attitude control systems that rely on Earth’s magnetic field. Non-magnetic interconnects ensure stable communication links without disturbing guidance or telemetry instruments.

3. Quantum Computing and Cryogenic Systems

Quantum computing represents one of the most magnetically sensitive frontiers in modern technology. Qubits, the quantum bits that carry computational information, are extremely sensitive to external magnetic fields. Even minor magnetic impurities in nearby materials can cause decoherence, leading to computational errors or reduced qubit lifetime.

Non-magnetic RF cables, connectors, and adapters play a key role in cryogenic environments, where temperatures drop below 10 Kelvin. These components provide low-loss signal transmission and maintain stable performance across temperature cycles—without contributing to unwanted magnetic noise.

In cryogenic setups, where precision and consistency are paramount, even a small magnetic interaction could invalidate experimental results. Hence, using non-magnetic hardware ensures reproducibility and protects the integrity of quantum and superconducting systems.

4. Test & Measurement and Metrology

In test labs, especially in RF and microwave metrology, the focus is on accuracy, repeatability, and minimal uncertainty. Instruments like spectrum analyzers, vector network analyzers (VNAs), and signal generators rely on calibrated interconnects to maintain stable readings.

When magnetic components are used in such setups, they can bias sensor readings or create unpredictable phase errors. For example, a magnetic connector near a current probe could influence the magnetic coupling, altering the measured waveform.

By contrast, non-magnetic interconnects help preserve measurement integrity by eliminating one more variable that could impact precision. This reliability is critical in calibration laboratories, national measurement institutes, and advanced R&D environments.

What Happens If You Don’t Use Non-Magnetic Components?

Neglecting non-magnetic designs in sensitive RF systems can have severe consequences. Here are some of the most common issues engineers face when magnetic materials are used inadvertently:

1. Field Distortion

Magnetic materials disturb surrounding magnetic lines of force. In MRI, this leads to warped imaging, and in navigation systems, it can bias magnetic sensors or disturb compass readings.

2. Increased Noise and Interference

Ferrous components can interact with oscillating fields, generating eddy currents that manifest as electrical noise or spurious harmonics. This noise can contaminate delicate low-signal paths or obscure weak signals.

3. Degraded System Performance

In RF circuits, magnetically active materials cause nonlinearities, signal phase drift, and impedance mismatch. Over time, this can lead to reduced system gain and efficiency, particularly in high-frequency applications.

4. Safety Hazards

In MRI or high-field lab environments, magnetic parts can be violently attracted toward the magnet bore, posing a serious hazard. This is why strict MRI safety protocols prohibit magnetic materials anywhere near the scanner room.

5. Reduced Measurement Accuracy

In metrology and test systems, magnetic interference introduces measurement uncertainty, potentially invalidating test data and necessitating recalibration.

Designing with Non-Magnetic Components

Creating a truly non-magnetic RF assembly requires more than simply avoiding ferromagnetic materials. Engineers must also consider plating, soldering, and assembly processes, as these can inadvertently introduce magnetic impurities.

For example:

- Nickel underplating commonly used for corrosion resistance is inherently magnetic. Replacing it with gold-over-copper or palladium provides a non-magnetic alternative.

- Stainless steel fasteners must be of austenitic grades (e.g., 304 or 316) to avoid magnetic response.

- Cable shielding materials should be carefully selected to balance magnetic transparency with EMI protection.

At Fairview Microwave, non-magnetic components undergo rigorous testing to verify magnetic permeability and RF performance, ensuring that every connector, cable, and adapter meets both electrical and environmental specifications.

Industry Implications

The shift toward non-magnetic RF and microwave components reflects broader trends in high-precision engineering. As technology evolves toward higher frequencies, smaller tolerances, and more magnetically sensitive environments, material purity becomes as important as electrical design.

From MRI scanners producing high-resolution diagnostic images to quantum computers performing delicate calculations at near absolute zero, non-magnetic components serve as the silent enablers of precision. They allow engineers and scientists to explore new frontiers in data fidelity, signal integrity, and measurement accuracy without the noise of magnetic interference.

Fairview Microwave provides a wide portfolio of non-magnetic RF/microwave components, including cables, connectors, and adapters, designed to perform flawlessly in high-field or magnetically sensitive environments.

Each component is manufactured with precision materials that exhibit near-zero magnetic permeability and consistent RF performance up to the highest frequencies. These products are ideal for medical imaging, aerospace, defense, quantum computing, and test labs, where signal purity and field stability are paramount.

Peter McNeil | Feb 12, 2025 | RF Interconnects

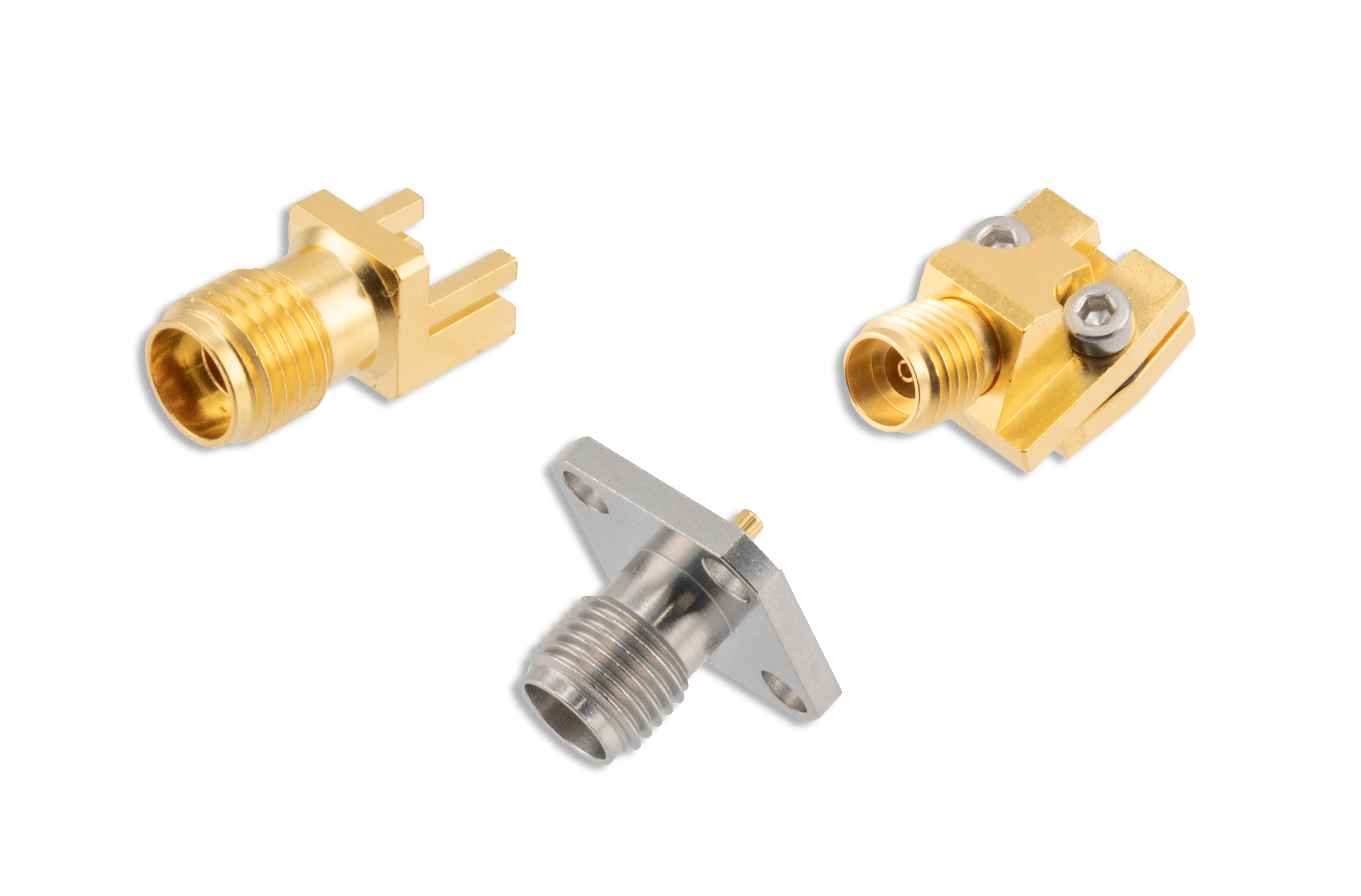

Designing high-performance RF systems often requires overcoming space limitations and optimizing signal routing with specialized components, such as angled PCB connectors. Unlike traditional straight connectors, PCB connectors allow for a more flexible orientation, making them ideal for compact designs where efficient use of space is crucial.

For example, when prototyping or working with tight spaces, the 1.85mm, female PCB mount vertical launch connector offers a clamp attachment design for easier installation. This product in particular supports up to 67 GHz performance, making it a reliable option for applications requiring high-frequency signal transmission.

Angled connectors like this one not only optimize space but also ensure that your system maintains low signal loss and high-frequency integrity, even when space is at a premium. Whether you're working on satellite communications, aerospace systems, or military radar systems, choosing the right connector can significantly enhance system performance.

Similarly, for applications requiring high-frequency performance and easy integration, products like the 2.4mm Jack PCB Mount End Launch and the 2.4mm Jack Solderless PCB Mount offer solutions that streamline installation and improve overall system reliability. With 50 GHz performance and minimal signal loss, these connectors are designed to meet the rigorous demands of high-performance systems.

How to Choose the Right Printed Circuit Board Connectors for Your Application

Selecting the appropriate RF PCB connectors for your system requires careful consideration of several factors, including the frequency range, VSWR (Voltage Standing Wave Ratio), mounting options, and the available space in your design. Each of these factors plays a crucial role in ensuring the efficiency and performance of your RF system.

· Frequency Range: The frequency range is one of the most important factors when choosing a connector. RF connectors that support up to 50 GHz, are ideal for applications that demand high-frequency performance. It's essential to select connectors that match the frequency requirements of your system to avoid signal degradation and ensure the integrity of your data transmission.

· VSWR: VSWR is an important indicator of signal integrity. A low VSWR ensures minimal signal loss, meaning your system can transmit signals with high efficiency. When evaluating connectors, always check the VSWR specifications to ensure they meet the requirements of your application.

· Mounting Options: The mounting method of your connector can have a significant impact on the ease of installation and the overall design of your system. End-launch connectors are excellent for systems where space constraints require a compact and efficient connector without sacrificing performance.

· Available Space: The physical space available in your design is another critical factor to consider. For systems with tight space requirements, narrow-body connectors high performance while occupying minimal space. These types of connectors are ideal for applications in military defense or satellite communications, where every inch of space matters.

Optimizing System Performance with the Right Connectors

Choosing the right connector can dramatically impact the performance of your RF system. For industries such as military defense, satellite communications, and RF testing, where precision is critical, high-performance connectors are a must.

These connectors also provide flexibility in routing and space-saving benefits that are essential in modern RF designs. Whether you need angled connectors for tight spaces or end-launch connectors for ease of integration, the right product ensures your system will operate at its best.

Future-Proof Your RF Designs with Top-Quality Printed Circuit Board Connectors

When designing your next high-performance RF system, consider the impact that these connectors and end launch connectors can have on your system’s performance. The connectors discussed here offer high-frequency performance, low-loss transmission, and the versatility required for demanding applications. Whether you’re working in telecommunications, military defense, or test & measurement, choosing the right connector ensures your system operates efficiently, even in tight spaces.

Our PCB connectors provide optimal signal integrity, reduced installation time, and ensure your systems perform at their best. Explore our range of high-performance RF PCB connectors today and get the reliability you need for your next big project.

Peter McNeil | Jan 03, 2024 | RF Interconnects

RF Interconnect is another term for RF connections between devices, boards, ports, RF cable assemblies, waveguide, probes, antenna, and etc. As discussed in a previous blog post, What is an RF Connection, RF interconnects are a method of transferring RF signals from one node to another either conductively, through a transmission line (RF coaxial connectors/ coaxial cable assemblies), or through a waveguide. It can be argued that an RF antenna is also a form of interconnect, though it is really a transducer that converts electrical signals carried conductively to a free-space wavefront.

When speaking of RF interconnect, this generally refers to connections between circuit boards, devices, subsystems, systems, and between interconnects. The reason RF interconnects are used, especially transmission lines and waveguides, is because containing the RF signal energy in a transmission line or waveguide is generally a much more efficient method of transferring that signal energy from one point to another, that signal is shielded to some degree from interference/noise injections from outside sources, and these types of connections help to ensure that the signal is harder to intercept, jam, block, or otherwise interfere with.

There are a variety of types of transmission lines and waveguides, as well as other types of RF interconnects. The most common types of RF transmission lines that most engineers and professionals are aware of are coaxial transmission lines. These make up the bulk of RF interconnects between modules, subsystems, and systems. Waveguides such as rectangular, circulatory, and elliptical waveguides are also commonly used for high power, precision, and extremely high frequency signals in the millimeter-wave range. There are other types of transmission lines, including planar transmission lines used on planar substrates/laminates, such as PCB, low-temperature co-fired ceramic (LTCC), high-temperature co-fired ceramic (HTCC), flex-PCBs, semiconductors, and others. Example planar transmission lines are coplanar transmission lines and striplines, of which there are a variety of configurations. There are also planar waveguides, such as a microstrip.

There are also a variety of different connector and adapter styles that should be included in the RF interconnect categories. These include adapters from different transmission line types, such as a planar transmission line to a coaxial transmission line, or between different types of coaxial connector types. There are also adapters between coaxial transmission lines and waveguides. It is important to note here that coaxial transmission lines are broadband RF signal carrying medium, while waveguides are banded based on the geometry and structure. Hence, any adapter between a coaxial transmission line and a waveguide will have a lower cutoff frequency limited by the waveguide and a higher cutoff frequency either limited by the coaxial transmission line or waveguide, whichever is lower.

It can be argued that certain resonant coupling structures can also be considered interconnects, as well as components such as directional couplers and probes. However, passive structures like directional couplers and probes are generally not considered RF interconnects as they lack a conductive path for the signals and rely on coupling to fields external to the conductors of the main RF signal paths.